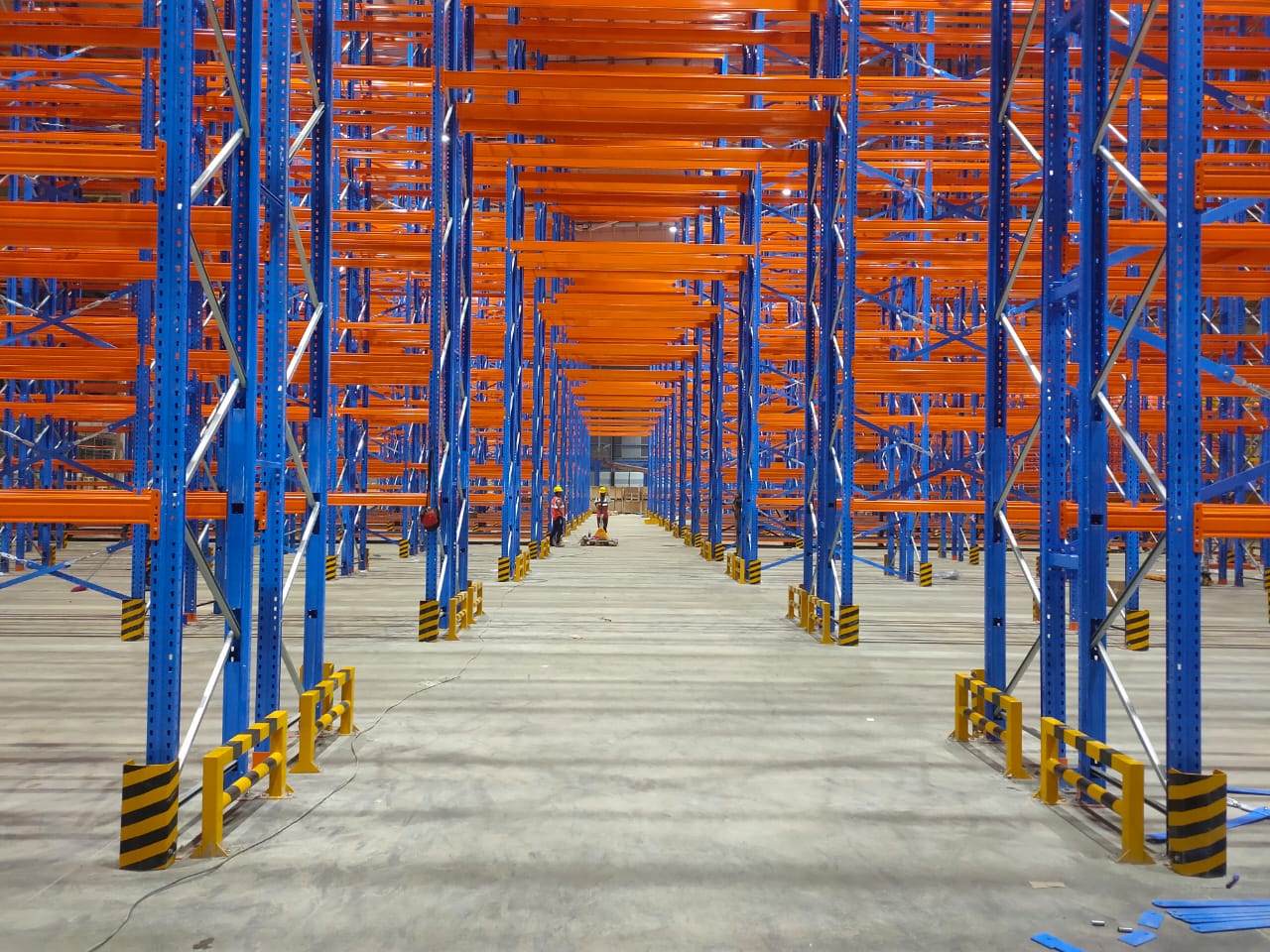

Rack Installation

Maa Tara Construction is a professionally driven all kind of Racking system Provider. We have a wide range of services to address customer requirements, primarily in the ware house infrastructure segments. We focus on quality, on-time execution, and cost control to reach the goal of satisfying our nationwide clients. In our journey of operation, we have been respecting each member of our team and our esteemed clients.

we offer a comprehensive range of installation services and mechanical, automation and civil services to help our clients experience a reliable, time-efficient, and global-standard supply of tools, tackles and machinery in the warehouse industries.

When you connect with Maa Tara Construction, you get benefits from the creativity and resources of our industry-leading experts.

Expect your desired services always with Maa Tara Construction. We ensure the highest level of satisfaction of our esteemed customers, even with their customized needs.

We use the most modern tools, tackles and machinery while working. Our experts are industry leaders with the highest level of experience. Quality of work has never been compromised throughout the journey of Maa Tara Construction.

We provide racking installation facility all over India, even we have done project in Nepal also. In fact India's biggest flipkart,s ware house which is located in Kolkata, whose area is 2.2 million square feet and that whole racking installation has also been done by our company. And the big think is that we did this project before dead line date.

We have experience to install various types of racking system.

- Selective Pallet Racking – Single/Double deep up to 18 metres of height

- Heavy Duty Shelving – G+5 up to 16 metre of height

- Mezzanine racking system (Column base and frame base)

- ASRS – Automated Storage and Retrieval Systems – Up to 29.6 metres of height

- Boltless racking system – up to 12.5 metres of height

- SAR – Slotted Angle Racks

- Mobistack racking system

- Radio shuttle / Auto shuttle racking system

- LSS – Long Span Shelving system

- PSS – Pallet Shelving system

These are some of the client’s warehouse list where we have installed Racking Systems.

- Flipkart (Kalash) – Haringhata

- Flipkart – Uluberua

- Amazon – uluberia

- Flipkart – Bagnan

- Reliance Retail – Srirampur

- Dalex Cargo – Panchala

- Iron Mounatin – Singur

- Berger paint

- Delivery – Mahindra

- Asian Paint

- Tata Motors

- Tata Steel

Automation Work:

Warehouse automation works by using software and technology like robotics and sensors to automate tasks. Warehouse automation helps ensure that business-critical operations in your facilities meet customer demand.

1. The implementation of Warehouse Automation and conveyor solutions run in tandem as the single most effective strategy to improve capacity, efficiency and reliability whist providing a reduction in operational costs. Combining the latest technology in both conveyor hardware and software is the stepping stone to reducing the complexities of running a modern warehouse. As specialists in logistics and automation, MAA TARA CONSTRUCTION have the tools and experience to deliver your project.

2. From the simplest transit conveyor through to a high-speed complex sortation project, MAA TARA CONSTRUCTION will work alongside you through all the key stages of the process. The flexibility in both the MAA TARA CONSTRUCTION approach and Automation/conveyor solutions provided.

3. We ensures that each solution meets each client’s specific requirements, and can be suitable for most warehouse applications ranging from start-ups to the most well-established operations in either an existing or brand-new site.

4. Maa Tara Construction has extensive knowledge of installation processes and conveyor systems. We’ll work with you to minimize workflow disruptions, respecting your deadline schedules and site requirements. Upgrading a facility or plant creates the risk of contamination. Dust, debris, and sparks threaten your products during the upgrade construction. Our crew will install temporary walls and barriers to seal construction zones. In many cases, your facility can continue normal work site operations as our team completes your conveyor installation or conveyor upgrade. Even in food plants, where sanitation is critical, we can control the potential hazards of construction during upgrades or repairs. We’re committed to keeping your people, property, and products safe.

5. The experts at Maa Tara Construction analyze your building’s structural constraints. We’ll make sure your facility can handle the added load of an automation system. Structural improvements also lead to removing obstacles. For example, while modifying a facility with structural upgrades, we can redesign facility layout to speed traffic flow, improve safety, and create more open space for materials handling.

Ware House Facilities:

Maa Tara Construction was also provided you a Ware House Facilities like Electrical work, CCTV related work and other miscellaneous work we well. We provide a complete solution at inside your ware house like dismantling, commissioning and other work also.

Steel Structural Fabrication and Erection:

we are executing Fabrication & Erection of Structural Steel Works in Refineries, Petrochemicals, Fertilizers, Steel Plants, Power Plants & other various new as well as expansion plants / projects.

1. Maa Tara Construction's commitment to 'Responsible Infrastructure' has stood the test of time, with social commitment and environmental responsibility being an integral business goal. We go beyond business, fulfilling our duty as a responsible corporate citizen. We consistently work towards improving the quality of life of the communities we serve, be it our organization, the industry as a whole, or society at large.

2. Since we execute some of the largest and most challenging projects in India, we take it upon ourselves to adopt sustainable practices that serve the well-being of the community - both in the immediate vicinity of its work operations and also beyond.

3. At MAA TARA CONSTRUCTION, we take pride in our work and strive for excellence, leading to results that speak of quality. Our prime focus is to meet the client's requirements and to strive to exceed their expectations. We strive to improve processes and methodologies to achieve consistent and predictable results. MAA TARA CONSTRUCTION aspires for zero-defect by creating an environment of quality awareness, rather than relying on inspections

4. We endeavor to effectively use Total Quality Management and six sigma tools to become the clients' most preferred choice by attaining excellence in quality and through timely completion of projects. We believe in recognition and empowerment, as well as enhancement of skills, to facilitate active and positive engagement of our people in achieving organizational objectives

5. At MAA TARA CONSTRUCTION, paramount importance is given to safety at every juncture, every step of the way. The company advocates efforts to achieve 'ZERO reportable injuries' at each work front. The company has undertaken several initiatives over the years to improve safety performance, including mandatory induction and training programs, tool box talks, demonstration of usages of personal protective equipment etc.

Piping Work:

Piping Installation or Erection refers to the laying of the piping system and its related accessories to make it ready for fluid transfer.

1. We follow proper piping installation codes and standards are key to safety and good operation. It is the next step to piping fabrication where pipe spools are made in the fabrication shop by cutting the pipes as per the accurate lengths and requirements.

2. Maa Tara Construction has experienced project team led by project managers responsible & accountable for each project. The project managers are ably supported by a group of professional’s experts in various disciplines. Thus, Maa Tara Construction provides a flexible & dynamic project management which is highly responsive and sensitive to customer needs. This allows, Maa Tara Construction to meet all the committed targets on time.

3. Maa Tara Construction, possesses young & dynamic professionals having requisite expertise which enables us to provide comprehensive turnkey solutions with single source responsibility. Zeal to explore our potential and vast hands-on experience in the industry gives us enough self-confidence to undertake projects of any complexities.

4. Over the years, acquisitions of a fleet of state-of-the-art equipment’s and other resources were made in order to provide one stop solution to our clients for executing the project from conceptual stages through execution to project delivery.

5. We appreciate every opportunity to be of service and are committed to providing reliable and professional service to our valuable clients. We believe and perform with a positive “CAN DO” Attitude with Safety in “Hearts and Minds” in all areas of our businesses.

Equipment Erection and Commissioning:

Erection, setting, adjustment, centering and alignment of hydro generating unit is a very complicated and specialized job. This has to be carried by expert and experienced team of engineers, technicians and helpers.

1. The Engineering Department of the Company consists of high-qualified and experienced staff, it is provided with advanced hardware and specialized application software, as well as with necessary regulatory and methodological base adapted to the up-to-date design and construction requirements.

2. The main activity of the Company in the field of engineering is focused on development, reconstruction, retrofitting and extension of automation and dispatching systems of oil-producing, oil-processing, petrochemical, chemical and other plants.

3. For mechanical systems, we provide pre-commissioning activities consist of cleaning and flushing of pipes, pressure testing, and leak testing.

4. For electrical systems, we provide pre-commissioning activities consist of panel energization, communication checks, loop checks (internal and external), and verification of any wiring to the central control room if required.

5. At the end of commissioning, we always go for the performance verification for customer satisfaction.